2020-08-26

Since the 1990s, terrazzo began to slowly withdraw from the historical stage and was replaced by other more dominant new materials, which has been silent for a long time.

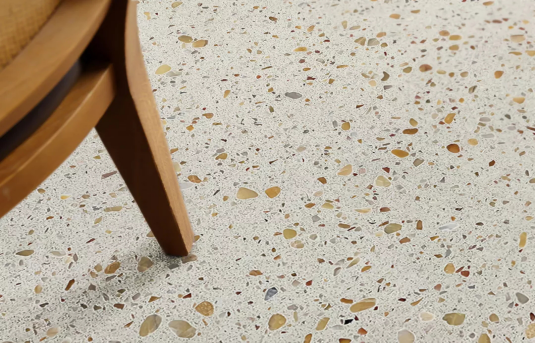

In memory, terrazzo is mostly used in large buildings such as schools and hospitals. The original cast-in-place terrazzo process is a product that has been ground and polished after mixing gravel, glass, quartz sand, etc. into cement. But always gives people a very common feeling.

With the huge breakthrough of process level and material quality, the new prefabricated inorganic terrazzo adopts environmentally-friendly inorganic adhesive, no resin glue, etc. It is made by high-frequency high-pressure vacuum vibration, with higher hardness and wear resistance, and more flexible construction. Convenience. With its stylish atmosphere, the design presents a sense of high quality.

How does the prefabricated terrazzo become

Designer's new favorite

01 rich patterns

Prefabricated terrazzo has an infinite variety of colors, and different stones interact with each other to create a new aesthetic combination. Leading the future with individuality without losing the classic design concept.

02 diversified design

The design of Weiyang Inorganic Terrazzo is diverse, with a high degree of plasticity, which can form a unique artistic pattern, geometric figures, and one-piece art basin. The theme of the gorgeous design is like a piece of art, both beautiful and timeless.

03 safe and durable

Wayon prefabricated terrazzo is resistant to fouling, corrosion, discoloration, odor and no pollution. It can be applied to interior and exterior floor tiles, wall tiles and dining tables. The overall space paving presents a fresh, elegant and minimalist European design language.

04 wear-resistant slip

Wayon prefabricated terrazzo has a low water absorption rate (as low as 1.1%) which is superior to the same industry standard. The surface of the rich stone color mix is shiny and beautiful. High wear resistance and surface hardness of 4-6. Can be seamlessly spliced to avoid dirt and scale, and will not cause thermal expansion and contraction.

SOUEAST Deepens Middle East Presence: Erbil Service Center and Spare Parts Warehouse Officially Launched

Chinese New Year in Jilin: A Snow & Ice Feast - The Festive Vibe at -20℃ ❄️🧨

A New Mobility Choice for Angola! SOUEAST S07 & S09 Make a Splendid Debut

SOUEAST's Newest S08 DM To Make UAE Debut at Dubai Fashion Week

Strong Compass Officially Launches the White Paper on Successful Strategies for the 2026 U.S. EB1A Program: Decoding Outstanding Talent Immigration Pathways in the AI Era with Data

Kaiyi Auto Exports Surge 233% in 2025, Leading Chinese Brands in Overseas Growth

©copyright 2009-2020 Singapore Info Map